RESIDUAL STRESS MEASUREMENT

VEQTER Ltd is a leading-edge spin-out company from the University of Bristol employing unique technology and expertise for residual stress measurement, analysis, and management in engineering components.

Currently serving many industrial sectors Worldwide, VEQTER is helping to reduce the frequency and duration of downtime that costs some clients more than £1,000,000 per day.

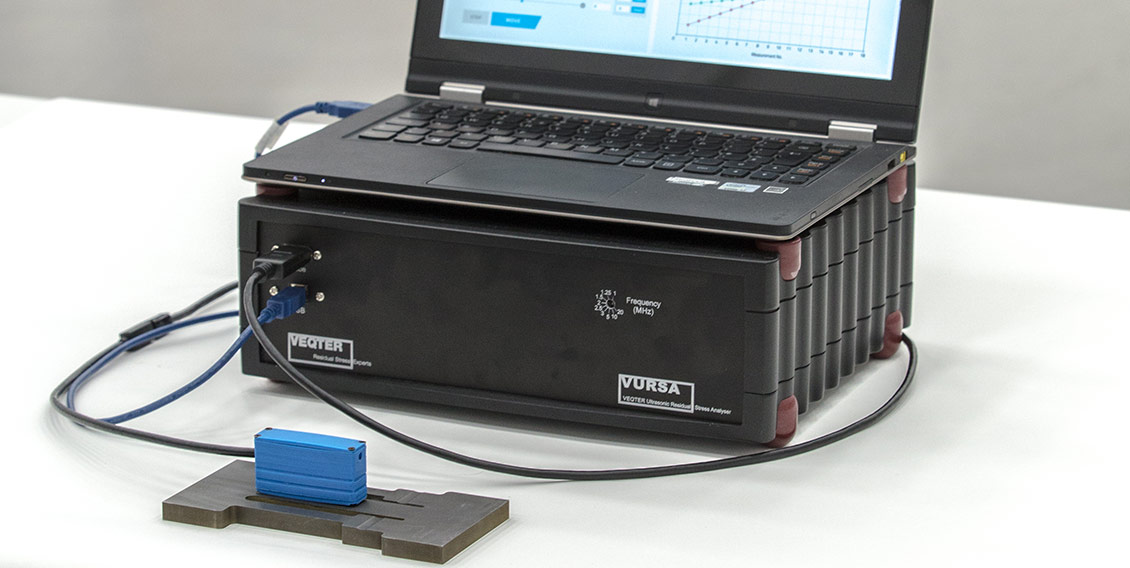

For residual stress measurement, we employ industry-proven methods and specialise in the Deep-Hole Drilling technique. Our portfolio of proven measurement techniques also includes Incremental Centre-Hole Drilling, Neutron Diffraction, Contour, Ring Core, Sachs Boring, Slitting, Synchrotron Diffraction, Ultrasound, and X-ray Diffraction. Through our experience and extensive knowledge of using these measurement techniques, we provide our clients with impartial advice on the optimum use of a wide-ranging portfolio of techniques to suit their requirements.

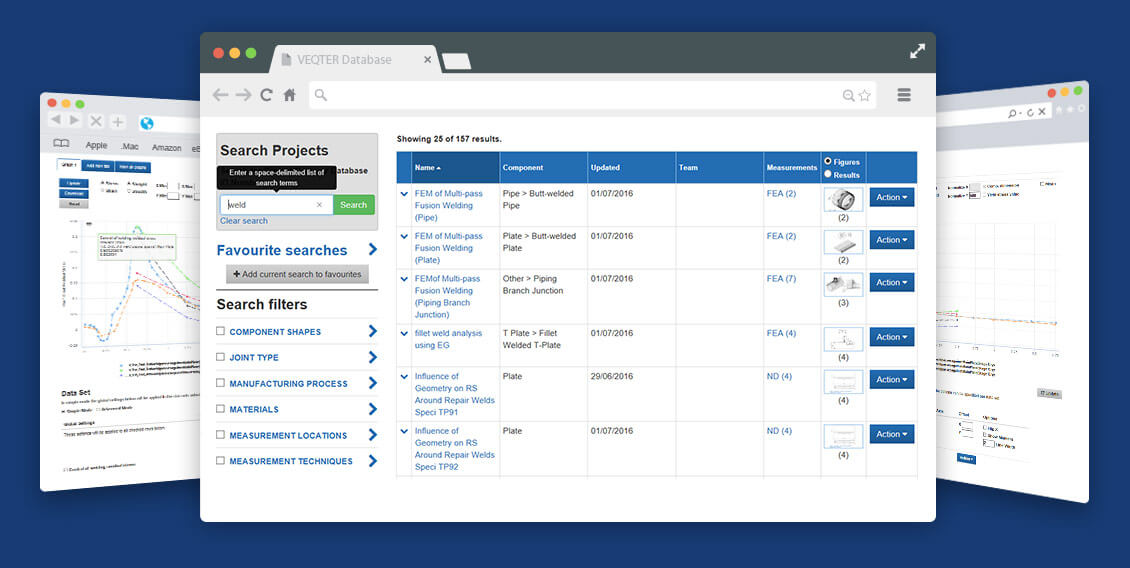

We provide our clients with complete through-thickness residual stress measurements from full-scale components, which prove vital in the next stages of structural integrity analysis. Using our advanced analysis tools, including our Residual Stress Database, we offer added insight into the residual stresses measured and their interpretation with respect to crack propagation, fatigue, manufacturing, numerical modelling, stress corrosion, and yielding, for example.

Our expertise in residual stresses extends to understanding their impact on the performance and structural integrity of engineering components, which include rotating machinery, pressurised systems, and major structures. We advise on the management and mitigation of residual stresses in circumstances where they are expected to be detrimental to performance.